- Why CERDAACWhy CERDAAC

- ProductsProducts

- SolutionsSolutions

- ResourcesResources

- CustomersCustomers

- CompanyCompany

In our eBook, Digitalizing Operations Quality in Regulated Environments, we share how leading lives at stake manufacturers are using a combination of lean Six Sigma practices and digital technology to significantly improve calibration, maintenance and other operations processes, along with some of the common pitfalls to avoid .

Digitalization is happening everywhere, both at home and in our work life. Recent trends show that we are embracing new digital technologies at an accelerating rate. Consider:

For highly regulated manufacturers in lives at stake industries, the benefits of digitalization are especially significant, including:

These manufacturers often face a sometimes conflicting challenge of continuously raising the bar on quality and regulatory compliance, while also constantly striving to deliver more products, more profitably. Those challenges are what make the promise of digital so compelling.

And yet, the promise of digitalization often goes unfulfilled. The digital projects that have the most promise are oftentimes the most complex and difficult to deploy. Despite the clear benefits, more than a third of software deployments struggle with avoidable pitfalls.

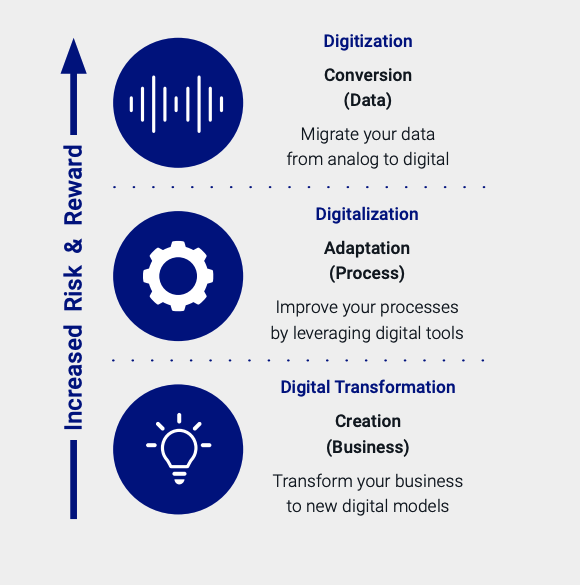

There are three main steps in the digital journey. Most organizations begin with digitization, simply taking analog data and putting it in digital form. The next step, digitalization, seeks to improve on that by leveraging digital data to drive real improvement in processes and workflows. The ultimate step in this journey is digital transformation: looking at whole new ways to bring value to customers by fundamentally transforming your business with new digital models. Think of Amazon’s journey from shipping physical books to selling electronic content, and creating whole new revenue streams in the process.

Download the eBook to learn how leading lives at stake manufacturers are using a combination of lean Six Sigma practices and digital technology to significantly improve operations quality processes, along with some of the common pitfalls to avoid when digitalizing your operations quality processes. We’ll also share some of the key takeaways learned from hundreds of software deployments with global manufacturers in the life sciences, aerospace, defense, and other highly regulated industries.