Asset inventory management blends elements of asset management and inventory management and encompasses the perpetual balancing of numerous moving parts. It calls for establishing standard operating procedures, and as a company grows, so does the criticality of these procedures. They become pivotal in scaling efforts and in ensuring operational efficiency.

Reliable asset management programs facilitate smooth operations, enhance customer satisfaction, and conserve costs across organizational lines.

Unfortunately, operational managers often delay setting up organizational systems to support asset inventory management. They underestimate its benefits and fail to generate enthusiasm amongst managers and stakeholders. This makes it much more complicated than it needs to be to motivate everyone to embrace its implementation. This post will hit all the high points to help change that mindset and make these processes a priority!

Understanding Asset Inventory Management Systems

Asset inventory management includes tracking, managing, and optimizing an organization’s physical and digital assets throughout their lifecycle. It’s a centralized platform for businesses to monitor and control assets, ranging from physical equipment like machinery and computers to intangible assets such as software licenses and intellectual property.

Assets are resources that generate positive economic benefits for organizations and help them achieve production and service objectives. And they span various categories, including operating, non-operating, physical, intangible, current, and non-current assets. Examples can encompass vehicles, machinery, furniture, computer equipment, intellectual property, and digital formats like videos, images, and various forms of documentation.

Inventory, meanwhile, encompasses raw materials utilized in production processes and finished products available for sale, categorized into raw materials, work-in-progress (WIP), finished goods, and maintenance, repair, and operations (MRO) inventory.

An effective asset inventory management system streamlines asset tracking across departments, ensuring access to up-to-date inventories. They track the movement of objects across organizational departments, streamline supply chains, reduce risk, and develop proactive maintenance strategies to better understand usage, changes, and lifecycle optimization. It might not sound super interesting, but it’s incredibly important. These materials are the foundation of a manufacturer’s offering.

So, what’s the difference between asset management and inventory management?

Asset Management vs. Inventory Management Systems

While both asset management and inventory management systems involve tracking organizational resources, they serve distinct purposes. Asset management systems focus on tracking asset details in real-time, including location and condition, aiding in better visibility into asset usage, costs, and maintenance. In contrast, inventory management systems track stock movement, optimize stock handling, forecast demand, and lower holding costs.

Asset management software tracks fixed assets, schedules maintenance, and calculates depreciation, while inventory management software controls inventory levels, enhances workflow efficiency, and provides real-time stock monitoring. Integrating both is key to comprehensive asset inventory management.

Assets and inventory forecasts can include a wide range of resources that companies may not already be tracking, including:

- Operating Assets: Assets directly involved in the production or delivery of goods and services, such as machinery, equipment, and vehicles.

- Non-Operating Assets: Assets not directly involved in operational activities, including investments, intellectual property, and land.

- Physical Assets: Tangible assets with a physical presence, such as equipment, vehicles, and infrastructure.

- Intangible Assets: Non-physical assets, such as patents, trademarks, copyrights, and goodwill.

- Raw Materials: Basic materials used in the production process to create finished goods, such as raw metals, fabrics, and chemicals.

- Work-in-Progress (WIP): Partially completed goods undergoing production but not yet ready for sale, representing products in various stages of completion.

- Finished Goods: Completed products ready for sale to customers, stored in inventory until ordered or shipped.

- Maintenance, Repair, and Operations (MRO) Inventory: Supplies and materials essential for maintenance and repair activities, ensuring smooth operational continuity.

And there are several steps that are essential for a successful inventory management system. They include:

- Creating Standard Operating Procedures (SOPs) to ensure consistency in asset management practices, guiding employees in asset handling, tracking, and maintenance procedures.

- Understanding customer needs and preferences helps align asset management strategies with customer expectations, enhancing satisfaction and retention rates.

- Optimizing asset utilization and maintenance processes to improve profit margins by reducing downtime, enhancing productivity, and minimizing operational costs.

- Implementing robust asset tracking systems to enable real-time monitoring of asset locations, usage patterns, and conditions to facilitate efficient resource allocation and decision-making.

- Proactively scheduling maintenance to ensure assets remain in optimal condition. This reduces the risk of unexpected breakdowns and minimizes maintenance costs.

- Developing proactive maintenance strategies based on asset performance data helps identify potential issues before they escalate, prolonging the lifespan of the asset and reducing downtime.

Asset inventory management offers numerous benefits, including informed decision-making, enhanced productivity, customer satisfaction, transparency, and simplified auditing. Tracking enables organizations to monitor asset location, users, and conditions accurately, using methods such as barcode labels, RFID, BLE, and GPS.

Asset tracking enhances accountability, streamlines maintenance, minimizes theft, and reduces administrative costs, contributing to business success by improving operational efficiency and employee productivity.

Selecting the right asset inventory management software involves considering factors such as customization options, scalable pricing, usability, flexibility, and customer support reputation.

What Are the Benefits of Asset Inventory Management Systems

Implementing asset inventory management systems offers several benefits to organizations. Streamlining asset tracking and maintenance processes enhances operational efficiency. Centralized asset management platforms facilitate efficient coordination of maintenance activities, ensuring timely servicing and minimizing disruptions to operations as there’s reduced downtime and resource utilization is maximized.

Lower operational costs should also be considered. Optimizing asset utilization, scheduling proactive maintenance, and minimizing unplanned downtime reduce maintenance and repair expenses, contributing to overall cost savings.

There’s also enhanced asset value estimation. Accurate asset tracking and condition monitoring enable organizations to better assess asset values, aiding in financial planning, reporting, and decision-making. And this informs future purchases. Analyzing asset performance data and maintenance histories helps organizations make informed decisions regarding future asset purchases, replacements, or upgrades, aligning investments with strategic objectives.

Choosing the right software can be tricky, though.

Choosing the Right Asset Inventory Management Software

When selecting the ideal asset inventory management software, it’s crucial to consider several must-have features, such as comprehensive asset tracking, maintenance scheduling, and customizable reporting functionalities.

Cloud-based solutions offer the flexibility of access from anywhere with an internet connection, facilitating seamless collaboration among team members across different locations. Integration capabilities are also key, allowing the software to sync seamlessly with existing systems such as ERP or CMMS platforms, streamlining data management processes.

Additionally, you’ll want to prioritize customizable options that allow you to tailor the software to fit your specific workflows and requirements. And a user-friendly interface is essential for ensuring smooth adoption by employees at all levels, so look for intuitive design and navigation.

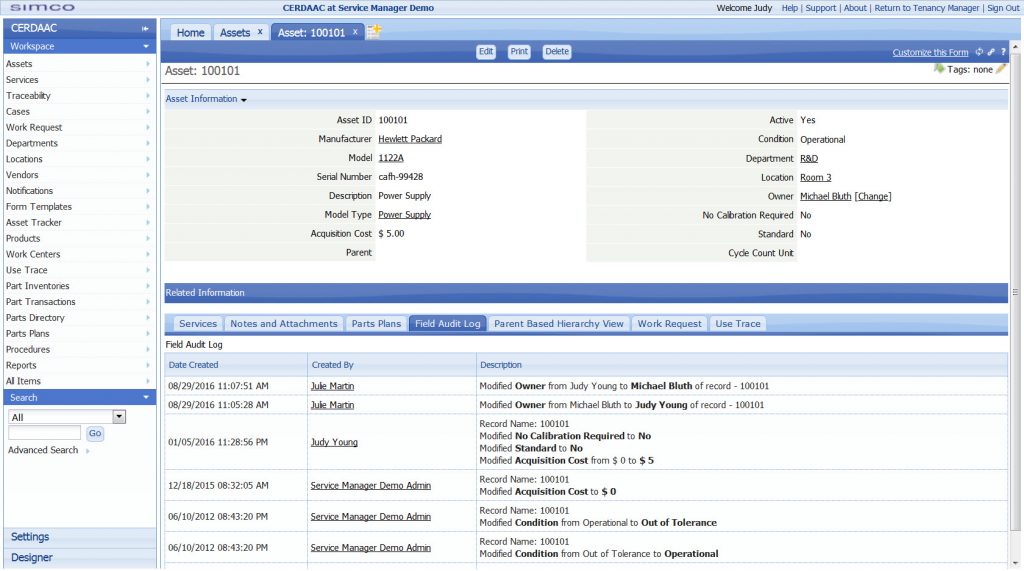

Scalability is another important consideration. As your organization grows, the software should scale with it without compromising performance or functionality. With these criteria in mind, CERDAAC is a comprehensive asset inventory management solution that ticks all the boxes.

Effective asset tracking may also include seeing the movement, location, and condition of parts. Scannable barcode labels are a widely used method. There is also RFID (Radio Frequency Identification) technology that utilizes radio waves, offering real-time visibility and precise location tracking. BLE (Bluetooth Low Energy) technology enables asset tracking using low-power Bluetooth signals, which is ideal for indoor tracking applications with short- to medium-range requirements. GPS (Global Positioning System) technology leverages satellite signals to track assets with high accuracy, which is suitable for outdoor tracking over large geographical areas.

Regardless of the method or technology employed, it’s essential to assign each asset a unique ID to avoid confusion and ensure accurate asset data management. And it also keeps your company up-to-date as new technologies emerge.

Revolutionizing Asset Inventory Management with IoT and AI

Understanding the potential benefits that the Internet of Things (IoT) and Artificial Intelligence (AI) offer is essential. IoT refers to the network of interconnected devices and sensors that collect and exchange data over the internet. In manufacturing, IoT-enabled sensors can be embedded in equipment, machinery, and other assets to monitor their performance, condition, and location in real-time.

These sensors continuously gather valuable data, such as temperature, vibration, usage metrics, and maintenance needs, providing manufacturers with unprecedented visibility into their assets.

By leveraging IoT, manufacturers can enable:

- Real-Time Asset Tracking: IoT sensors enable real-time tracking of assets throughout the manufacturing facility. Manufacturers can monitor the movement of assets, identify their current location, and optimize their utilization, leading to improved operational efficiency.

- Predictive Maintenance: By analyzing data collected from IoT sensors, manufacturers can predict potential equipment failures before they occur. Predictive maintenance algorithms use AI to identify patterns and anomalies in asset behavior, enabling proactive maintenance interventions. This approach minimizes downtime, reduces maintenance costs, and extends the lifespan of assets.

- Inventory Optimization: IoT-enabled inventory management systems provide manufacturers with accurate and up-to-date inventory information. By monitoring inventory levels in real-time, manufacturers can prevent stockouts, minimize excess inventory, and optimize supply chain operations.

AI technologies, such as machine learning algorithms and predictive analytics, complement IoT sensors by analyzing vast amounts of data to extract actionable insights and automate decision-making processes. In asset inventory management, this emerging technology is set to offer several benefits, including:

- Predictive Insights: AI algorithms analyze historical data to identify patterns and trends, enabling manufacturers to make data-driven predictions about future asset performance and maintenance needs. By anticipating issues in advance, manufacturers can take proactive measures to prevent disruptions and optimize asset utilization.

- Automated Task Management: AI-powered asset management systems automate routine tasks, such as inventory tracking, maintenance scheduling, and workflow optimization. By eliminating manual interventions, manufacturers can reduce human errors, improve efficiency, and allocate resources more effectively.

- Optimized Resource Allocation: AI algorithms optimize resource allocation by analyzing production schedules, inventory levels, and asset availability in real-time. By dynamically adjusting production processes and inventory levels based on demand forecasts and asset availability, manufacturers can minimize waste, reduce costs, and improve overall productivity.

As manufacturing continues to evolve, embracing these technologies will be game-changing. But that’s not the only way the field is evolving. Sustainability measures are gaining prominence as well.

Enhancing Environmental Sustainability Through Asset Inventory Management

In the global manufacturing landscape, environmental sustainability has become a pressing concern. As industries strive to reduce their carbon footprint and minimize environmental impact, the role of asset inventory management in promoting sustainability has gained significant attention. By implementing efficient asset inventory management practices, manufacturers can not only improve operational efficiency but also contribute to environmental conservation efforts. Here’s how:

Efficient Resource Utilization

One of the key ways asset inventory management contributes to environmental sustainability is through the efficient utilization of resources. By maintaining accurate records of assets and inventory, manufacturers can optimize resource allocation and minimize waste.

Real-time tracking of assets allows for better visibility into inventory levels, ensuring that resources are utilized effectively, and excess inventory is minimized. This results in reduced material consumption, energy usage, and greenhouse gas emissions, ultimately contributing to a more sustainable manufacturing process.

Waste Reduction and Recycling

Asset inventory management systems enable manufacturers to identify opportunities for waste reduction and recycling. By tracking the lifecycle of assets and monitoring their condition, manufacturers can implement proactive maintenance strategies to extend asset lifespan and minimize the need for replacements.

Additionally, inventory management systems help identify surplus or obsolete inventory that can be repurposed or recycled, reducing the amount of waste sent to landfills. By implementing circular economy principles, manufacturers can minimize environmental impact and promote resource conservation.

Energy Efficiency and Emissions Reduction

Effective asset inventory management facilitates better energy management practices, leading to increased energy efficiency and reduced emissions. By monitoring asset performance and identifying inefficiencies, manufacturers can implement energy-saving measures such as equipment upgrades, maintenance optimization, and operational adjustments.

IoT-enabled sensors and predictive analytics help identify energy-intensive assets and prioritize energy-saving initiatives. This not only reduces operational costs but also lowers carbon emissions, contributing to environmental sustainability goals.

As sustainability becomes an increasingly important consideration for businesses worldwide, integrating environmental considerations into asset inventory management practices will be essential for driving positive environmental outcomes and ensuring long-term viability in a changing world. Contributing to a greener future will become table stakes.

It’s Time to Tailor Success & Focus on Customization

Efficiency and precision are paramount in manufacturing, and asset inventory management stands as a cornerstone of success. However, one size does not fit all when it comes to managing assets effectively.

To address the unique challenges and requirements of diverse manufacturing environments, customization and personalization in asset inventory management software play a pivotal role. They empower manufacturers to optimize operations and support MRO excellence.

Manufacturing industries vary widely in terms of processes, equipment, and regulatory requirements. What works for one sector may not necessarily apply to another. Customization allows asset inventory management software to be fine-tuned to meet the specific needs of each industry. Whether it’s medical devices, pharmaceuticals, or aerospace, tailored solutions ensure that workflows are optimized, compliance standards are met, and operational efficiency is maximized.

The manufacturing landscape is in a constant state of flux, with new technologies, market demands, and regulatory changes reshaping the industry. Customizable asset inventory management software offers the flexibility needed to adapt to evolving challenges. Whether it’s adding new data fields, integrating with emerging IoT devices, or accommodating changing reporting requirements, customizable solutions empower manufacturers to stay agile and responsive in a rapidly changing environment.

Customization allows manufacturers to streamline workflows and automate routine tasks, thereby increasing efficiency and reducing errors. By configuring the software to align with existing processes and workflows, manufacturers can eliminate unnecessary steps and optimize resource allocation. And personalized automation features enable proactive maintenance scheduling, real-time alerts, and it empowers manufacturers to preemptively address issues before they escalate.

By understanding industry-specific needs, enhancing user experiences, and streamlining workflows, customized solutions empower manufacturers to optimize efficiency, reduce costs, and achieve sustainable growth. As manufacturing continues to evolve, tailored asset inventory management solutions will remain indispensable tools for success.

Future Trends in Asset Inventory Management

New trends are emerging that promise to reshape the way manufacturers track, manage, and optimize their assets. Here are a few and their potential impact on the manufacturing industry:

Blockchain Technology for Asset Tracking

One of the most promising trends in asset inventory management is the increasing reliance on blockchain technology. Blockchain, a decentralized and immutable ledger, holds the potential to revolutionize asset tracking by providing a secure and transparent platform for recording asset transactions and movements.

By leveraging blockchain-based solutions, manufacturers can create tamper-proof records of asset ownership, provenance, and maintenance history, thereby enhancing transparency, reducing fraud, and improving supply chain efficiency.

IoT Integration: Empowering Smart Manufacturing

The integration of Internet of Things (IoT) devices is another key trend shaping the future of asset inventory management in manufacturing. IoT sensors embedded in machinery, equipment, and products enable real-time monitoring of asset performance, condition, and location.

Manufacturers can gain valuable insights into asset utilization, maintenance needs, and workflow optimization by harnessing IoT data. IoT-powered asset inventory management systems empower manufacturers to embrace the principles of smart manufacturing, driving productivity, efficiency, and innovation.

AI, Machine Learning and Automation

Artificial Intelligence (AI) and Machine Learning (ML) technologies are poised to play a significant role in the future of asset inventory management. By analyzing historical asset data, predicting maintenance needs, and optimizing asset utilization, AI and ML algorithms enable manufacturers to make data-driven decisions and automate routine tasks.

AI-powered asset inventory management systems can detect anomalies, identify patterns, and recommend optimal asset management strategies, thereby improving operational efficiency, reducing downtime, and maximizing asset lifespan.

And as manufacturing continues to evolve in the digital age, the future of asset inventory management holds immense promise and potential. The convergence of these future trends promises to revolutionize asset inventory management, driving innovation, efficiency, and competitiveness in the manufacturing industry. Reach out for a demo and we can show you best in class options for tracking your assets today, and ways to prepare for tomorrow!